Foshan Zhongyong Automation Equipment Co., Ltd. is a national high-tech enterprise that has specialized in the research, development, and manufacture of intelligent pipe welding machines since 2010. Zhongyong has demonstrated a commitment to the advancement of technology in the field of pipe welding. This commitment has been formalized through the establishment of a research and development center focused on pipe welding technology, staffed by a team of seasoned professionals.

The company has historically engaged in collaborative endeavors with scientific research institutes, and its technological advancements have been extensively adopted in the production equipment of the welded pipe industry. These contributions have enabled the industry to undergo a technological upgrade, remain at the forefront of industry trends, and transition from a predominantly experiential to a digitally and intelligently driven model.

One-stop digital control

One-stop digital control

The one-stop digital control platform realises the intelligent management of the whole production process, relying on the Ethernet server to build the data hub system, collecting, storing and transmitting the production line data to the customer terminal in real time, and supporting remote parameter setting and equipment regulation. The group control system integrates the operation of multiple production lines, realises the digital seamlessness from production planning, on-site execution to quality control, monitors the status of the equipment in real time, traces the fault information, effectively reduces 30% of the management cost and improves 50% of the decision-making efficiency, and comprehensively pushes the production system to the intelligent transformation and upgrading.

Adopt cantilever HMI, operating at any angle, the HMI can control and monitor the data of the production line from forming section, welding section, grinding section, sizing section, cutting section and unloading frame.

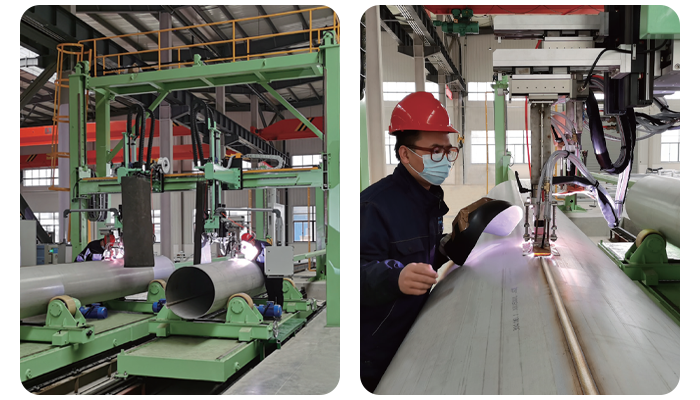

Collected with precision automated machinery, laser detection, digital control, remote monitoring and management technology, the production line realizes intelligent production, one person can operate multiple production lines.

Machine bed and frame of horizontal rolls and frame of vertical rolls are made heating treatment after forming, elimination stress, rough process and refine process to ensure the precision of equipment.

The production line has an intelligent shutdown function; the system calculates the shutdown position, and then automatically stops the whole production line.

The stand house is processed by a horizontal CNC machining center, which can ensure the accuracy of the stand house by clamping. The stand house and the slider have good assembly compatibility, and the upper horizontal shafts can move up and down smoothly; a parallel line is built in all the stand houses, which lays a foundation for the center line to each section.

Unique mechanical structure, the height of the welding roll sets can be adjusted simply by the side adjusting screw, adjustment simple and install welding protection box conveniently.

One-integrate digital control of welding tooling and welding power, precision and stability.

Can store and use 100 different sets of welding specifications.

Cantilever type HMI, objective and convenient, easy to operate.

Ethernet interface can transmit the equipment state, production data, energy loss and so on to the PC terminal, mobile terminal,MES,ERP for seamless connection.

one button start, top welding, reduce the tedious operation of the normal equipment to achieve the automatic welding effect.

The parameters of the digital wire feeder are set on the touch screen, and the full closed-loop feedback control technology is adopted. The wire feeder speed in the welding process is uniform, and the weld forming is beautiful.

The pulse arc is adopted to prevent the interference of traditional high frequency arc to the system.

The welding history data can save the current ,voltage,welding speed, wall thickness, pipe diameter of the welding process to the welding system for the collection and inspection of production parameters,and the data can be printed and copied on site.

The trolley for is driven by servo motor,welding speed stable and the welding seam is beautiful.

Two welding monitoring cameras are installed on the welding head, one monitoring the welding molten pool and another monitoring the welding quality after welding.